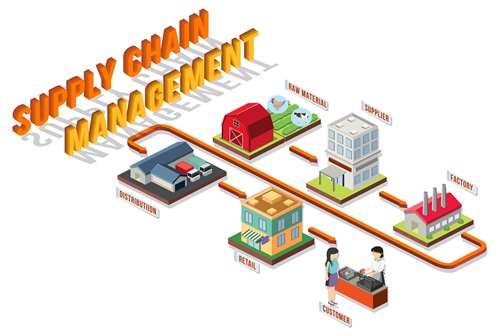

Introduction to Supply Chain Management

Supply Chain Management (SCM) is the process of managing the flow of goods, information, and finances as they move from raw material suppliers to end consumers. SCM ensures each stage, from sourcing materials to delivering the final product, is efficiently coordinated. In today’s globalized world, effective SCM is pivotal for business success and competitiveness. Organizations rely on SCM to meet consumer demands, reduce operational costs, and sustain a reliable supply network.

Key Components of Supply Chain Management

Supply Chain Management encompasses several crucial components that work together to create a smooth, efficient supply process. These components include:

- Planning: Strategy formation and forecasting demand.

- Sourcing: Procuring materials and establishing supplier relationships.

- Production: Manufacturing processes and quality control.

- Inventory: Managing stock levels and storage.

- Transportation: Distribution of goods from production to consumers.

- Return: Handling defective or excess products for return or recycling.

Each element requires careful management and integration to ensure the entire supply chain operates as a cohesive unit, minimizing delays and maximizing profitability.

The Role of Supply Chain Management in Business Success

An efficient supply chain is a cornerstone of any successful business. With optimized SCM, companies can reduce production and logistics costs, which directly impacts profitability. Moreover, a streamlined supply chain improves customer satisfaction by ensuring products are available when needed. SCM also aids in reducing waste and enhancing quality by aligning all stages in the production process, leading to both short-term and long-term business growth.

Types of Supply Chain Models

Supply chain models can vary based on a company’s goals, resources, and product types. Common models include:

- Push Model: Products are manufactured based on forecasted demand, common in industries with stable demand patterns.

- Pull Model: Production is based on actual demand, providing flexibility but requiring responsive manufacturing.

- Agile Model: Suitable for industries with unpredictable demand, emphasizing flexibility and quick response.

- Lean Model: Focuses on reducing waste and maximizing value, ideal for stable and high-demand products.

- Hybrid Model: Combines push and pull approaches for balanced efficiency and flexibility.

Selecting the right model is crucial as it impacts costs, responsiveness, and customer satisfaction.

Supply Chain Planning and Strategy

Planning is essential in SCM to anticipate market demands, manage resources, and set realistic objectives. Supply chain strategy is shaped by a company’s goals, whether focused on cost reduction, service improvement, or market expansion. A strong SCM strategy aligns with a business’s overall objectives and sets a foundation for informed decision-making at each supply chain stage.

Supply Chain Design and Network Configuration

Designing an effective supply chain involves structuring the network in a way that minimizes costs and meets demand efficiently. Network configuration includes the layout of facilities, transportation routes, and storage locations. By optimizing these elements, businesses can reduce transit times, lower storage costs, and improve delivery times, enhancing customer satisfaction.

Inventory Management and Control

Inventory management is the process of overseeing stock levels to ensure a balance between having sufficient supply to meet demand and minimizing holding costs. Techniques such as Just-In-Time (JIT), Economic Order Quantity (EOQ), and ABC analysis help businesses maintain optimal inventory levels. Proper inventory management prevents stockouts and excess storage costs, crucial for maintaining profitability and operational efficiency.

Procurement and Supplier Relationship Management

Procurement involves sourcing raw materials or products at favorable terms, while Supplier Relationship Management (SRM) builds partnerships with reliable suppliers. SRM promotes trust, quality assurance, and timely delivery. Developing strategic relationships with suppliers enhances a business’s ability to manage costs, access better materials, and negotiate favorable terms, all of which contribute to a stable and efficient supply chain.

Logistics and Distribution in SCM

Logistics is the backbone of SCM, responsible for the movement, storage, and distribution of goods. Effective logistics ensures products are delivered in the right quantities, to the right locations, and at the right time. Distribution focuses on how products reach consumers, whether through direct delivery, warehousing, or retail channels. Together, logistics and distribution determine the speed and reliability of a company’s product availability, directly impacting customer satisfaction.

Technology in Supply Chain Management

Advancements in technology are transforming SCM. Key technologies driving this change include:

- Artificial Intelligence (AI): For demand forecasting and process automation.

- Blockchain: Ensures transparency, traceability, and security.

- Internet of Things (IoT): Real-time tracking and monitoring of goods.

- Big Data and Analytics: Insights for better decision-making.

These technologies improve accuracy, speed, and efficiency across the supply chain, giving businesses a competitive edge.

Demand Forecasting and Management

Accurate demand forecasting allows companies to predict consumer needs, optimize inventory, and plan production accordingly. Techniques like statistical analysis, AI-driven models, and market analysis enable businesses to respond quickly to shifts in demand. Effective demand management aligns production with demand, reducing waste and avoiding stockouts, ensuring the right products are available when customers need them.

Risk Management in Supply Chain

Supply chains face numerous risks, including supplier disruptions, natural disasters, and economic fluctuations. Effective risk management involves identifying potential risks, assessing their impact, and implementing measures to mitigate them. Strategies include diversifying suppliers, developing contingency plans, and using insurance to cover potential losses. Proactive risk management helps businesses maintain stability and avoid costly disruptions.

Sustainability and Ethical Practices in SCM

Sustainability in SCM focuses on minimizing environmental impact through eco-friendly sourcing, reducing waste, and promoting recycling. Ethical practices involve fair labor standards, transparent supplier relationships, and community responsibility. Companies that prioritize sustainability and ethics enhance their brand reputation and attract conscious consumers who value responsible business practices.

Challenges in Supply Chain Management

SCM comes with its share of challenges, including:

- Supply Chain Disruptions: Natural disasters, pandemics, or political instability.

- Demand Fluctuations: Unpredictable market trends and consumer behavior.

- Rising Costs: Increasing transportation, fuel, and raw material costs.

- Regulatory Compliance: Navigating complex regulations.

Addressing these challenges requires a flexible, well-prepared strategy and an ability to adapt to changing conditions.

Future Trends in Supply Chain Management

The future of SCM is driven by innovation and adaptation. Trends include an increased emphasis on automation, data analytics, artificial intelligence, and digital twins—virtual models of the supply chain for better decision-making. Additionally, as consumers grow more conscious, there will be a stronger focus on sustainability, transparency, and ethical sourcing. These advancements are shaping a more efficient, resilient, and consumer-centric supply chain landscape.

Conclusion

Supply Chain Management is vital for any business looking to thrive in a competitive market. From procurement to logistics, effective SCM ensures products are delivered cost-effectively and on time. With technological advancements and strategic planning, businesses can optimize their supply chains to not only reduce costs but also boost customer satisfaction and long-term success.

FAQs:

Supply Chain Management involves planning, sourcing, production, logistics, and inventory management to ensure efficient product flow from supplier to consumer.

Technology enhances efficiency, accuracy, and transparency, enabling better forecasting, real-time tracking, and automated processes.

Push supply chains rely on forecasted demand, while pull supply chains produce goods based on actual demand, offering greater flexibility.

Sustainable SCM practices reduce environmental impact, appeal to eco-conscious consumers, and enhance brand reputation.

Risk management helps identify and mitigate potential disruptions, ensuring supply chain continuity and stability.